Explain Various Drivers Of Supply Chain Performance

CHAPTER ONE Discussion Questions1. Consider the purchase of a can of soda at a convenience store. Describe the various stages in the supply chain and the different flows involved.When a customer purchases a can of soda at a convenience store, his purchase represents the end of a supply chain’s delivery of an item and the beginning of information regarding his purchase flowing in the opposite direction.

The supply chain stages include customers, retailers, wholesalers/distributors, manufacturers, and component/raw material suppliers. A customer’s purchase moves product towards the customer and dollars and information towards the retailer.The retailer places an order from the. Finally, the procurement cycle connects the manufacturer and the supplier. The manufacturer requires raw material inputs of paper, ink, etc., to begin the assembly process for another batch of Supply Chain Management. The push/pull boundary exists where demand switches from reactive (pull) to speculative (push) production. For most bookstore supply chains the push/pull boundary is between the customer order cycle and the replenishment cycle. The customer order pulls the book from the book store shelf but the initial production of the book was triggered by a build order that moved materials along the supply chain to the retail outlet.5.

Consider the supply chain involved when a customer orders a book from Amazon. Identify the push/pull boundary and two processes each in the push and pull phases.In Amazon’s original operations design the push/pull boundary existed betwixt the retailer (Amazon) and their distributor.

Amazon ordered product from the distributor and the customer order arrived. New super mario bros wii midi files. Today, Amazon has six warehouses where it stocks an inventory of items it is confident that will sell. In this scenario, the push/pull boundary exists between the customer and the retailer. Processes in the pull phase are the order fulfillment, shipping, customer returns, and customer billing. Processes in the push phase are production, stock replenishments, shipping,.

8921 Words 36 Pageswww.iiste.orgDrivers of Supply Chain Performance Enhancing Organizational Output: An Exploratory Study for Manufacturing SectorIrum Shahzadi, Saba Amin, Kashif Mahmood Chaudhary. President GCUF Toba Tek Singh Group Department of Business Administration, Government College University Faisalabad, Pakistan. Tel: +83, E-mail: kashifmahmood5970@yahoo.com, www.km5970.webs.com Abstract Purpose - The Purpose of this study is to explore the drivers of supply chain performance and give a framework. 3068 Words 13 PagesSUPPLY CHAIN RISK MANAGEMENTIntro: It is too difficult to give one and distinctive definition of Supply Chain Risk management (SCRM). Indeed, Sodhi, Son, and Tang (2012) begins their findings with the similar fact that ‘there is no clear consensus on the definition of SCRM (because some restrict the scope of SCRM to rare but large impact events while other authors believe that SCRM is about demand-supply uncertainties. 1/3rd of their analysis did not just show that respondents took a probabilistic.

2492 Words 10 PagesPURCHASING AND SUPPLY CHAIN MANAGEMENT ANALYSIS OF TWO COMPANIESTESCO AND ASDASummaryI have chosen to do the assignment on comparing these retail giants over their purchase and supply chain management and its key issues. I was working for a firm in india which is indulged in day to day purchase and supply and was not much effective. It was the main reason to do a research on these firms and to discover how do they handle such an effective supply chain management. Researching on key issues. 2159 Words 9 PagesTBS908 – Supply Chain ManagementAssignment 1: ReportThe role of Information Technology and Globalisation in Supply Chain ManagementBYAKHIL DOMINIC4468119Submitted toDr. Albert MunozFaculty of BusinessUniversity of Wollongong – Sydney Business SchoolMARCH 2015ContentsIntroduction3Objectives of Supply Chain Management:3Impact of Globalization in SCM:4Driving Forces of Globalisation:4a) Global Market Forces5c) Global Cost Forces5d) Political and Macroeconomic Forces. 2368 Words 10 Pagesand Supply Chain Managementby Vinod LallExecutive Summary.

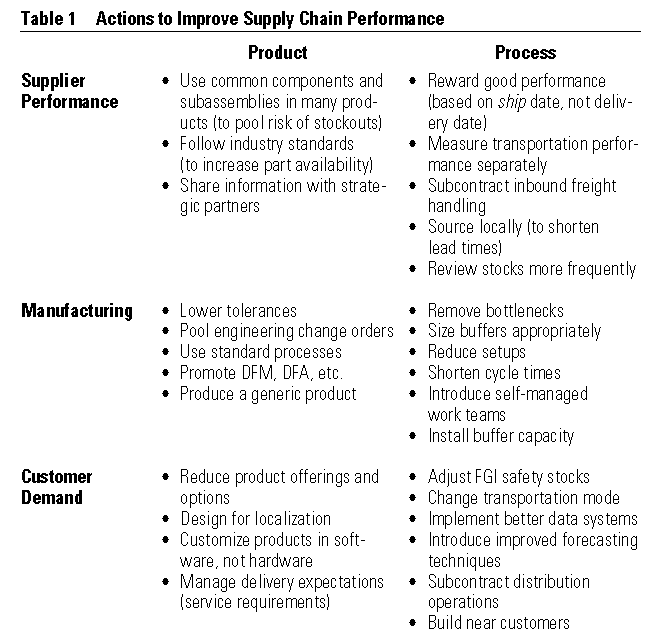

There are numerous drivers of production and the supply chain, and there are several processes under each driver. These processes are associated with high overheads and offer opportunities for cost reduction. Cost reduction requires a complete knowledge and mapping of all costs, cycle times, purchases, inventories, suppliers, customers, logistics, and other service providers throughout the supply chain. Cost reduction in the supply chain. 1758 Words 8 Pagesin the data.Applicability of various forecasting techniquesFrom the analysis in the previous section, it is clear that the NHS data has a strong Trend and is Seasonal. The applicability of the right forecasting model would involve a detailed understanding of the key features of the most recognized time series models.

The key features of the NHS data based on the qualitative and visible information is summed below:Data FeaturePrevalenceTrendHighSeasonalityHighImpact of External FactorsModerate. 4571 Words 19 PagesGlobal Competitiveness: Role of Supply chain ManagementBusiness today is in a global environment. This environment forces companies, regardless of location or primary market base, to consider the rest of the world in their competitive strategy analysis. Firms cannot isolate themselves from or ignore external factors such as economic trends, competitive situations or technology innovation in other countries, if some of their competitors are competing or are located in those countries. 4069 Words 17 Pages1.0 Executive SummaryThe report details the findings on Toyota Motor Corporation's supply chain management in great description. Areas that will be covered in the report include the supply chain processes of Toyota, supply chain strategies that it adopts and the practical use of drivers that determine the performance of the entire supply chain in terms of responsiveness and efficiency.The supply chain processes and strategies of Toyota are the fundamentals in its daily operations. 3881 Words 16 Pageslines working 24 hours per day for 6 days per week throughout the year.

Healthpartners

So elaborate planning and control over the production is crucial for meeting customer deadlines as well as for better inventory management. The inventories in iNova consist of supplies, raw materials, components, in-process goods and finished goods. It is necessary for it to holds some inventory for protection against unanticipated or unplanned occurrences.The strategic goal of the company is to double the business in every 5.